Home Products Automatic Rigid Box Making Machine HM-DP4030M Automatic Rigid Box Machine (

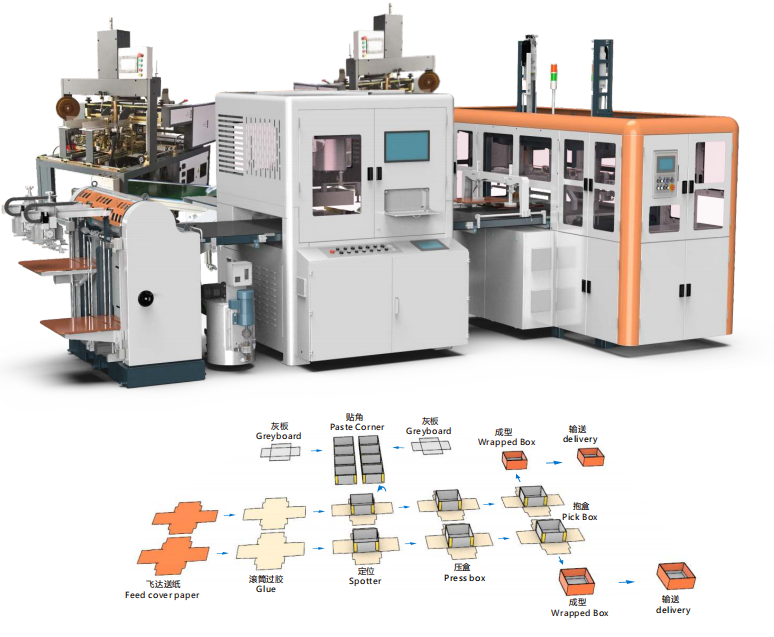

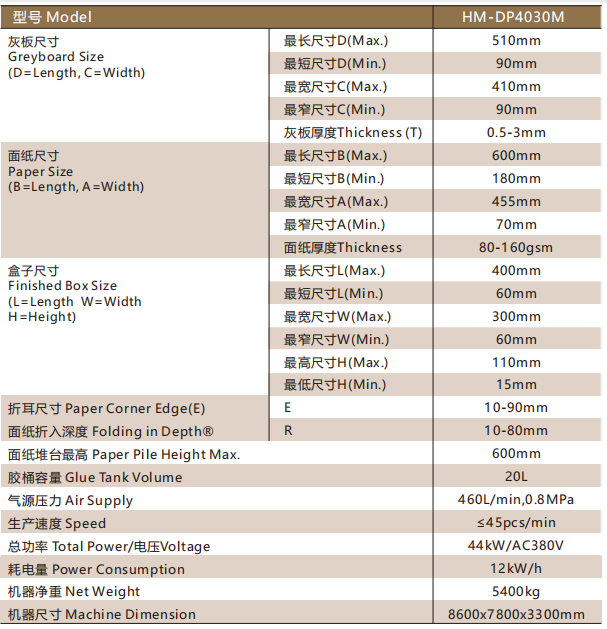

HM-DP4030M Automatic Rigid Box Machine: engineered to produce a variety of large premium boxes, including those for mobile phones, jewelry, cosmetics, and watches. This dual-channel machine stands out with its high-speed production capabilities, perfectly catering to the demands of the modern packaging market.

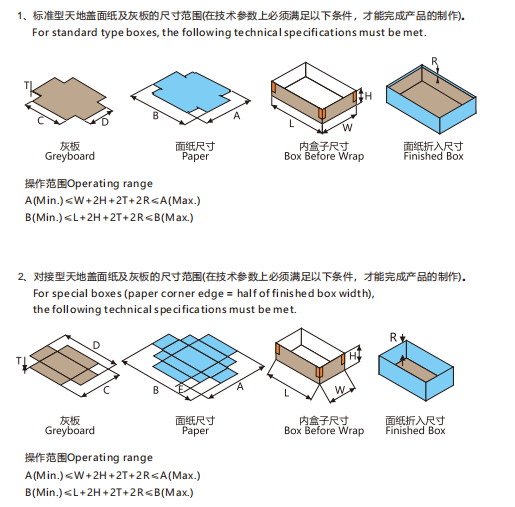

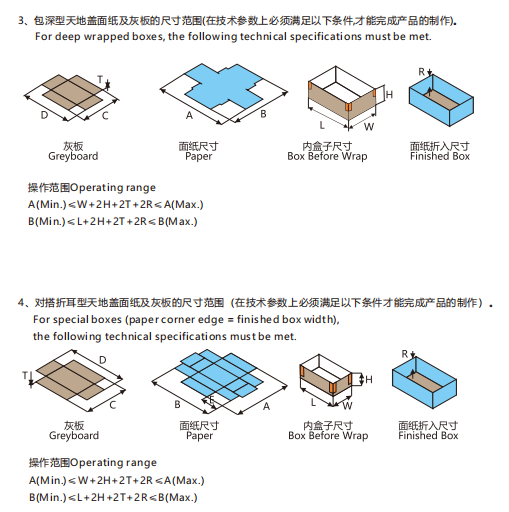

The machine's updated design not only enhances safety but also improves aesthetics. It utilizes a sophisticated servo control system and an image positioning system to automate the entire box-making process, including paper feeding, gluing, grey board feeding, four-corner pasting, positioning, box holding, edge wrapping, ear folding, and final folding.

Key features include:

The HM-DP4030M sets a new standard in the packaging industry, combining cutting-edge technology with user-friendly features to deliver unmatched performance and versatility.

Notes:

Name: Yvette Wang

Mobile:+86 13829101603

Whatsapp:+86 13829101603

Email:yvettewang18@gmail.com

Add:Niushan Qiantou Xinxing Industry Park Dongcheng District Dongguan City Guangdong China

We chat