Production of Luxury Packaging Rigid Box- Hongming

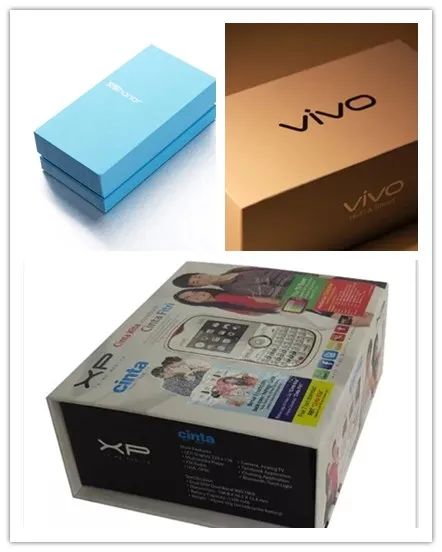

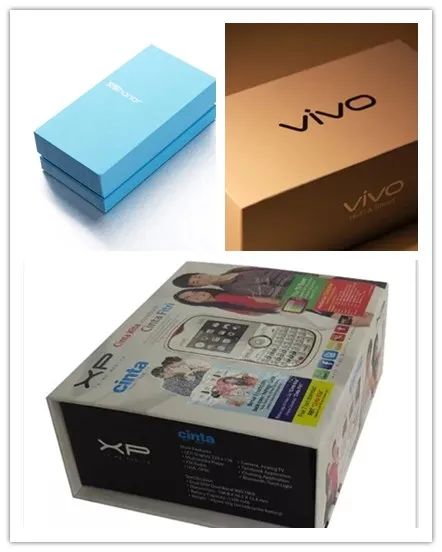

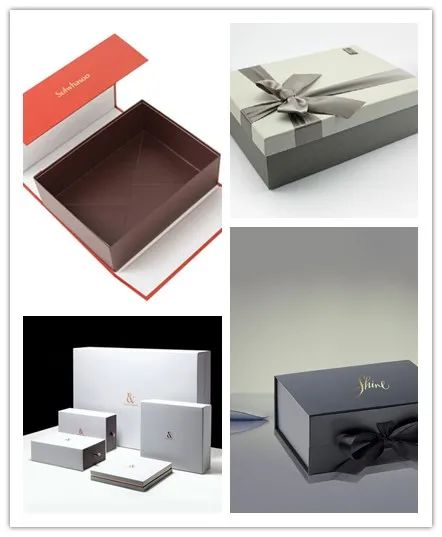

The appearance of the luxury rigid box packaging box is also one of the important means to attract consumers. Consumers will judge the quality of the product and whether the brand is trustworthy by the texture of the outer packaging.

Whenever traditional festivals come, the products are full of festive items, and we will buy festival-related gifts in shopping malls or online, such as the Dragon Boat Festival and Mid-Autumn Festival that we have recently been impressed by, we found that in moon cake boxes, rice dumpling boxes In the cover of the packaging box, the suppliers will print the festive special pattern on the cover of the packaging box, which not only shows the traditional national culture, but also reflects the artistry of the packaging shape, shows the beauty of the product, and attracts consumers. The beauty of the shape shapes the appearance characteristics and national style characteristics, making the product packaging a work full of artistic interest and the spiritual connotation of national culture.

After October, the number of holidays increases, and the demand for stocking on "Double Eleven", New Year's Day, Spring Festival and other festivals increases, and product packaging is also in great demand. At that time you will see a variety of holiday-specific merchandise. Dazzling array, different shapes, but the first thing that catches the eyes of consumers is the packaging box of these gifts. At the same time, major merchants will work hard on the printing design of packaging boxes to attract consumers' attention, in order to make their products stand out from many competing products.

The exquisite presentation of an outer luxury rigid box packaging box not only includes the cover printing design, but also requires the production of box-making equipment. Only the high-quality production of basic box-making equipment can determine the quality of the box's appearance and texture.

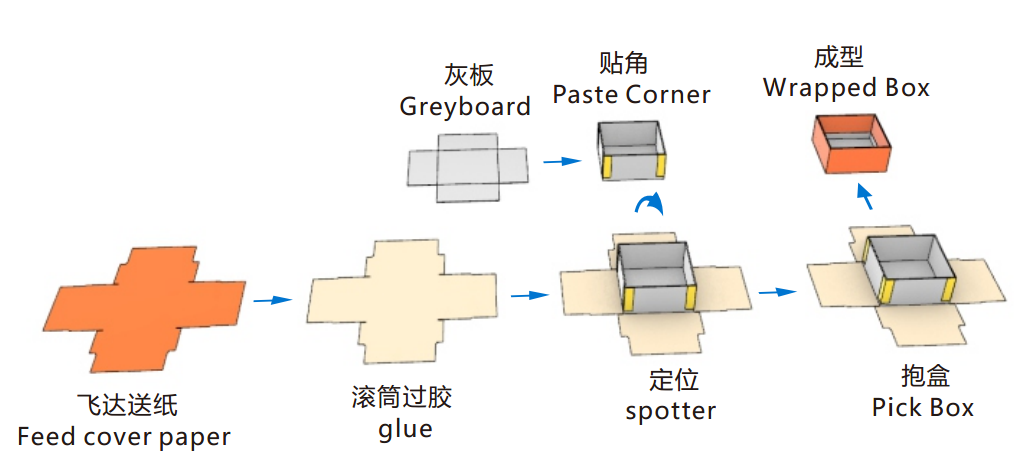

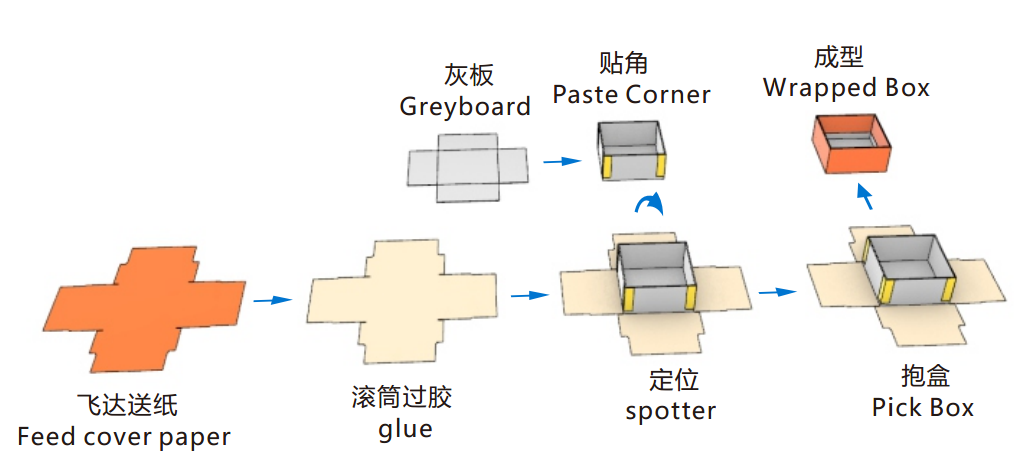

In the production of boxes, the process of box-making equipment is particularly important. First of all, the most important materials are face paper and gray board. The paper needs to be die-cut, laminated and other pre-processing. The gray board also needs to be die-cut or slotted. , and then go through production processes such as face paper gluing, corner beating, positioning and forming. And this series of processes can be fully automated.

HM-ZD6418D automatic box making machine, high-level box-making process equipment, adopts double-station box-making production, automatically absorbs and feeds paper, and automatically alarms when faults are diagnosed online. The operation and maintenance are simple, the operation is stable and the efficiency is high. Intelligent parameter adjustment, automatic gluing, 24-hour control of glue temperature and uniformity, whole machine servo control, image positioning, high precision, and a wide range of box types.

Features

intelligent

Automatic control, intelligent adjustment

Intelligent diagnosis, simple control

Automatic gluing, uniform gluing

Automatic alarm, automatic paper feeding

efficient

High precision box making

High production efficiency

Wide range of box types

save

Small footprint

Low consumption of raw materials

Only 1-2 people can control it

flexible

Conveyor belt replacement is easy, saving time and effort

Hongming supplys different kind mahcines for luxury rigid box such as gift box, cosmetic box, jewerly box, gift box, wine box etc.