Rigid Setup Box Production Process

1. Design, according to requirements, culture, and product characteristics, etc., design patterns.

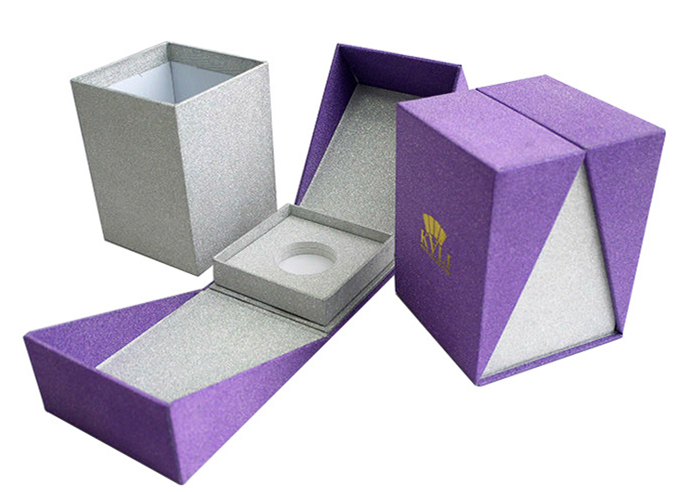

2. Proofing, according to the drawings, make samples. The present gift box pays attention to the appearance of beautiful and beautiful, so the color of the version is also varied. Usually, a style of gift box not only has 4 basic colors but also several special colors, such as gold and silver. These are all special colors. Handmade bamboo basket packaging, Pure and original ecology, novel design, sturdy and durable, low-carbon and environmentally friendly, can be widely used in the packaging of agricultural and sideline products such as fruits, fungi, eggs, food, pickled and preserved products.

3. Choose cardboard. The general rigid setup box cardboard box is made of cardboard. High-grade wine packaging and gift packaging boxes. Most of the cardboard with a thickness of 1mm-4mm is used to manually mount the outer decorative surface, and bond and form.

4. Printing, the gift box only uses the printing wrapping paper, the cover paper will not be printed, and at most it is only dyed, because the gift box is an outer packaging box, so the printing requirements are very high, and the most taboo is color difference, ink spots, bad version These disadvantages affect the aesthetics.

5. Surface treatment, the wrapping paper of the gift box , rigid setup box, cardboard boxes usually needs surface treatment, the common ones are over-glazing glue, over-matte glue, over-UV, over-varnish, over-matte oil.

6. Die cut is a more important link in the printing process. If the die cut is to be accurate, the die must be accurate. If the die cut is not accurate, biased, and not deep enough, which will affect the subsequent processing.

Name: Yvette Wang

Mobile:+86 13829101603

Whatsapp:+86 13829101603

Email:yvettewang18@gmail.com

Add:Niushan Qiantou Xinxing Industry Park Dongcheng District Dongguan City Guangdong China

We chat