Home Products Automatic Rigid Box Making Machine HM-ZD240 Automatic Rigid Box Making Mach

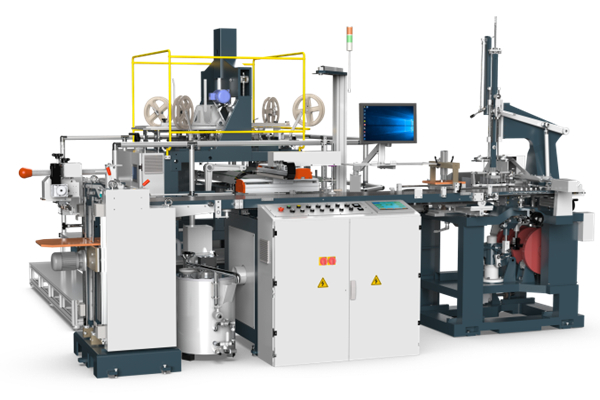

HM-ZD240 Automatic rigid box machine

HM-ZD240 Automatic box maker with high accuracy spotter (the positioning error ± 0.05). And with the production of the part of the special-shaped box, specialty paper, plastic boxes, and other complex production process. The molding product Smallest 45 * 35 * 10mm. For the machine detailed electronic components constructed, welcome customers visit.

The machine is suitable for all kinds of high-grade jewelry boxes, watch boxes, pen boxes, gift boxes, candy boxes, souvenir boxes, jewelry boxes, cosmetics boxes and other small size box manufacturing production.

Features and function:

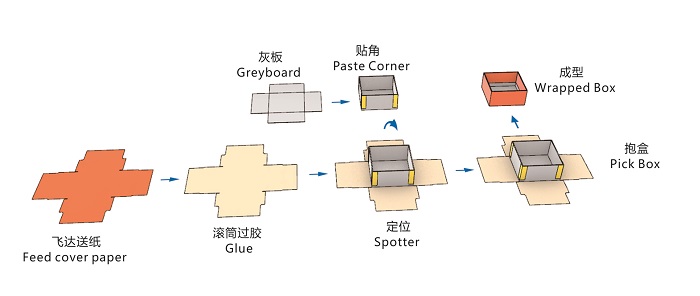

1. Suitable for all kinds of rigid boxes automatic production

2. Computer control with auto error display and malfunction display.

3. Automatic feeding cover paper and cardboard.

4.24 hours control glue pre-heating

5.Hot-melting adhesive automatic conveying, cutting and finish pasting the inner box quad stayer(four angles) of cardboard in one process.

6. The vacuum suction fan under the conveyer belt can keep the glued paper from deviating.

7. The box-forming unit can automatically collect boxes and deliver them to the forming unit. The box-forming unit can continually delivery boxes, wrap sides, fold ears and paper sides and form in one process.

8. Spotter unit apply high tech camera with 8 million pixel ( spotter accuracy± 0.05mm. )

9. The whole machine employs PLC, photoelectric detector system and touch screen man-machine interface to automatically form boxes in one process.

10. It can automatically diagnose the troubles and alarm accordingly.

11. Remodel for automatic production of different kinds of boxes ( optional)

12. Automatic control system for glue viscosity ( optional)

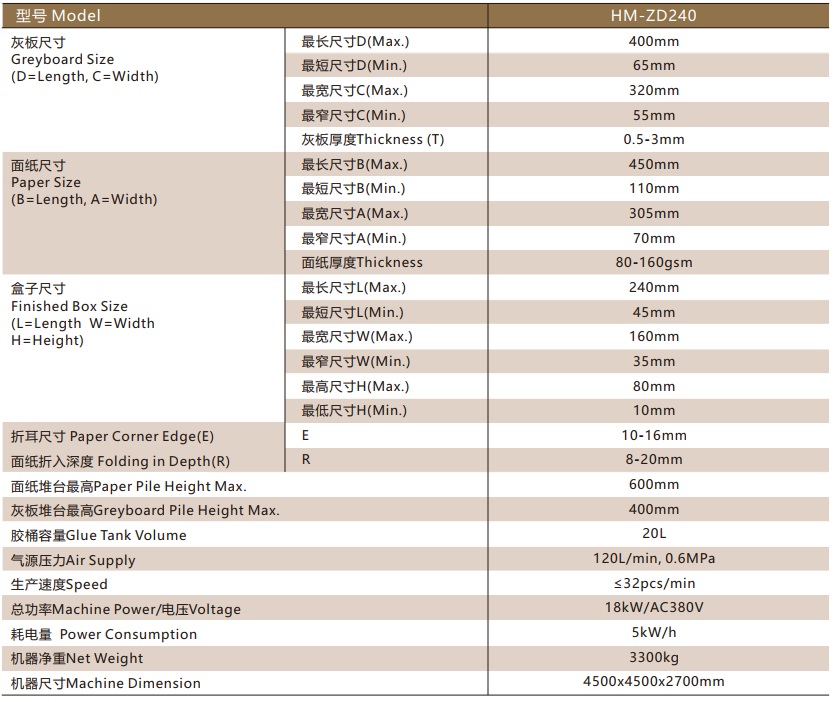

Technical parameters:

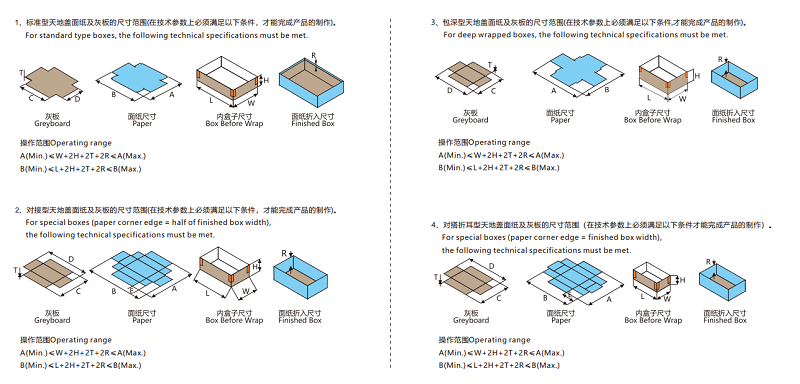

Note:

1.The max. size and the min. size of box are determined by the max. and min. size of cover paper.

A( Min.)≤W+2H+2T+2R≤A(Max.);B( Min.)≤L+2H+2T+2R≤B(Max.)

Max. Length, width and high can’t reach max. at the same time. Min. Length, width and high can’t reach min. at the same time.

2.The production speed of the rigid box maker is determined by the box size, paper and cardboard materials.

3.We don’t provide air compressor. (8 atm=0.808MPA , 7.5KW compressor with dryer is needed)

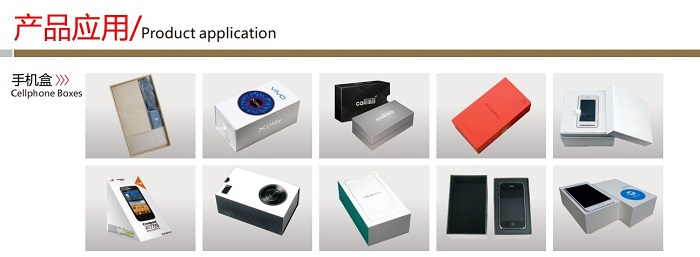

Box Appplication:

Name: Yvette Wang

Mobile:+86 13829101603

Whatsapp:+86 13829101603

Email:yvettewang18@gmail.com

Add:Niushan Qiantou Xinxing Industry Park Dongcheng District Dongguan City Guangdong China

We chat