Home Products Automatic Rigid Box Making Machine HM-ZD2418 Automatic Rigid Box Making Mac

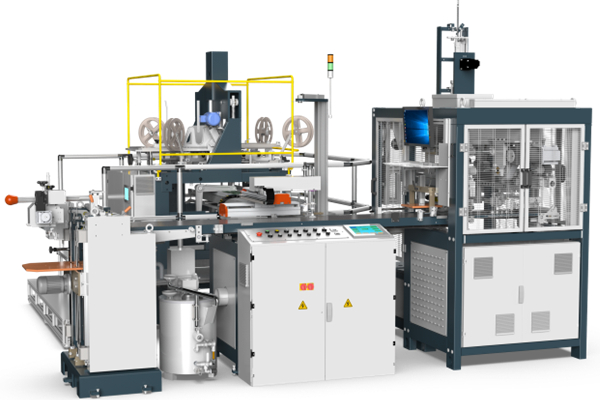

HM-ZD2418 Automatic Rigid Box Making Machine

HM-ZD2418/2418PLUS Automatic Rigid Box Line is specialized in mass producing all kinds of small rigid boxes, such as finest jewelry boxes, ornaments boxes, gift boxes, watch boxes, pencil boxes, candy boxes, souvenir boxes, and cosmetic boxes, etc, which covers the ring boxes. It is the smallest automatic box maker in China.

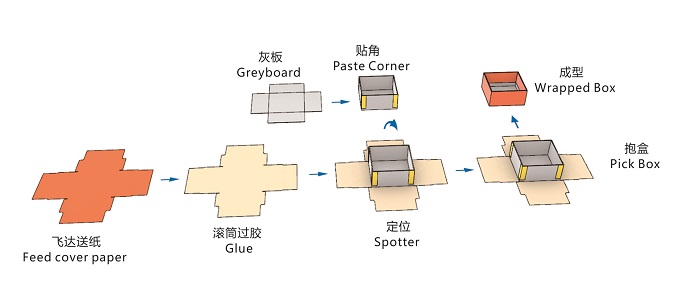

This machine adopts PLC and man-machine control, error auto stop and display, camera tracing system, and can automatically feed coverpaper, feed greyboard, paste four corners, spot greyboard, lift box, wrap box, fold corner edges and form box.

The feeder, gluer and conveyor are driven by servo system which has continuously variable transmission and enjoys high accuracy, easy adjusting, and less time consumption. Double color conveyor can save the time for changing to other color belt, which is Hongming’s patent. The spot unit adopts Germany camera with 5 million pixel and robot arm to pick and spot the greyboard, enhancing the spotting accuracy to ±0.05mm. The forming unit employs Germany linear slider, stable and wear resistant.

Features and function

1. Suit to all kinds of rigid boxes in mass production;

2. Computer control with error auto stop and display;

3. Adopt servo and PLC;

4. Automatically change mould(optional);

5. Automatically feed paper and greyboard;

6. 24-hours control for glue pre-heating;

7. Input 300 product formula, and add 2G memory SD card(optional);

8. Automatically cut and heat tape to paste the greyboard box’s quad stayer (four corners), with independent man-machine control;

9. Spotter by camera tracing system and robot arm(spotting inaccuracy ±0.05mm);

10. Wrapper can automatically and continually deliver box, wrap paper, fold corner edge, fold in and form box;

11. Automatic control system for glue viscosity(optional).

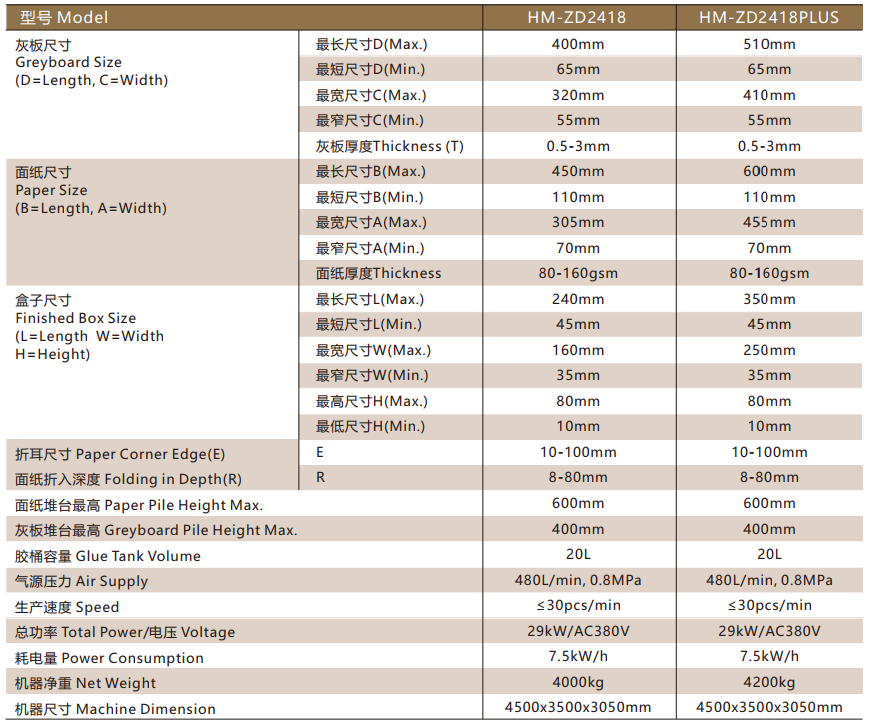

Technical parameters:

Note:

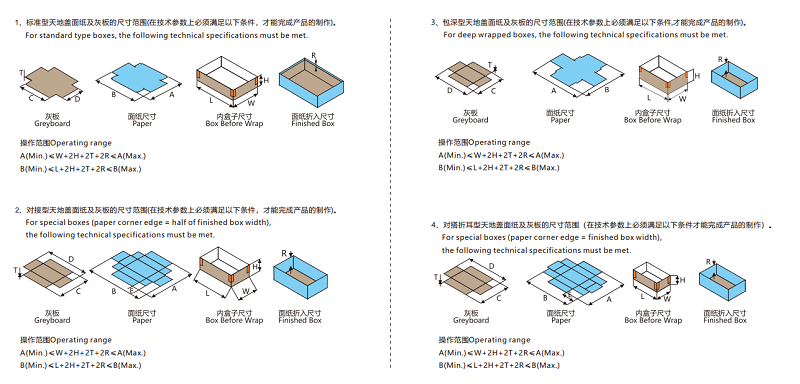

1.The max. size and the min. size of box are determined by the max. and min. size of cover paper.

A( Min.)≤W+2H+2T+2R≤A(Max.);B( Min.)≤L+2H+2T+2R≤B(Max.)

Max. Length, width and high can’t reach max. at the same time. Min. Length, width and high can’t reach min. at the same time.

2.The production speed of the rigid box maker is determined by the box size, paper and cardboard materials.

3.We don’t provide air compressor. (8 atm=0.808MPA , 7.5KW compressor with dryer is needed)

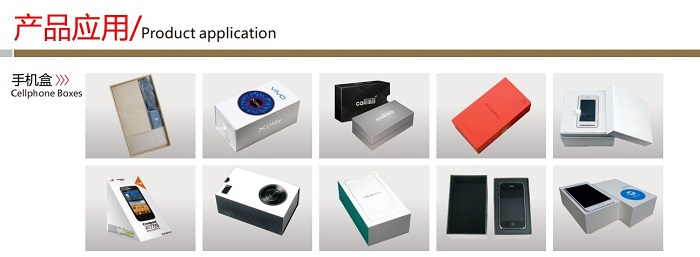

Box Appplication:

Name: Yvette Wang

Mobile:+86 13829101603

Whatsapp:+86 13829101603

Email:yvettewang18@gmail.com

Add:Niushan Qiantou Xinxing Industry Park Dongcheng District Dongguan City Guangdong China

We chat